Be sure to scroll through completely, as you'll find we swapped many upgrades and tested a ton of components! This bike has been built several times over, getting better every time.

We next added a much-needed shift light to the OEM dash. We went with the PZRacing Lightronic unit, which looks similar to what came on our Motec-based factory SBK.

This is a big upgrade to the wimpy OEM light.

After that, we cleared out a ton of space in the tail with an FTECU ABS ECU Delete.

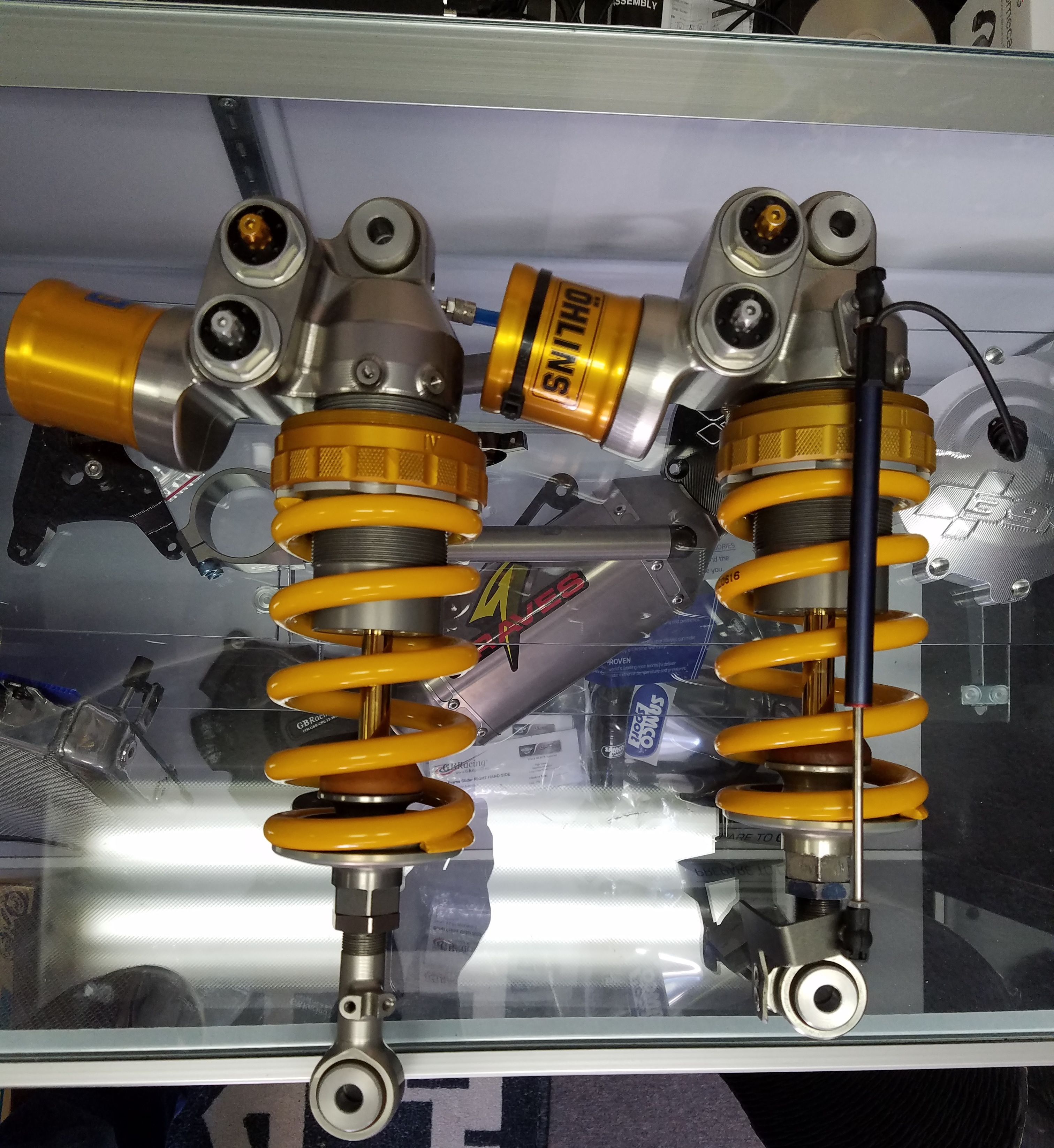

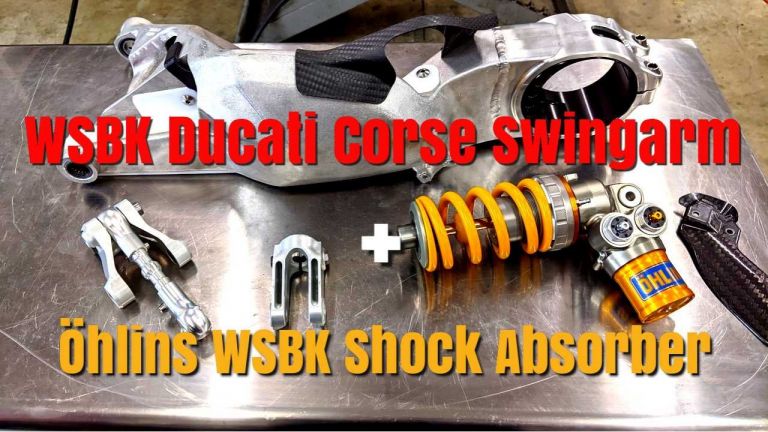

We are also now using a new shock/link arm combo that is helping with rear grip, as well as tire longevity.

We've added some new Zeta parts, like the remote adjuster, clutch perch and RCS half lever.

Next, did a set of custom forks in-house.

Special anti-stiction coating, ultra-low friction seals/wipers and fork cap extenders to give a little more range of adjustment.

Next, Winter testing was in full swing!

We're testing out some electronics changes, forks and brakes. We'll also be testing one of our team's brand new ZX-10R race bikes. We'll be doing some 2018 ZX-10R / ZX-10RR Superstock and Superbike projects alongside the continuing evolution of the R1. We won't bore you guys with those Kawasakis here though!

Winter testing is not complete without a proper winter test livery – why should factories have all of the fun?

This bodywork was intended to be temporary and certainly not long-term. While we used this, our Lacomoto superbike bodywork kit was with Andrew Swenson for out 2018 season livery.

We were also fortunate enough to secure an Ohlins RSP40 World Superbike shock absorber, which is the best of the best and extremely difficult to locate. These are typically only available to factory teams at the highest level.

We next got a long-awaited and beautiful upgrade, an SE Moto carbon fiber superbike subframe and monocoque undertail.

Our good friend Guy Halbrooks also made us this awesome upper shock shaft in titanium.

We also secured the new Ohlins YA 468 TTX GP shock absorber for testing, this features an all-new compression piston & valving, as well as a long-awaited hydraulic preload adjuster.

Next, we got our beautifully painted bodywork back from Andrew Swenson and naturally installed it right away.

Next, we got some custom CoreMoto brake lines, which are absolutely incredible. Fantastic build quality and tons of customization options. These feature titanium fittings as well:

Then, we decided to swap out our Brembo calipers for a set of Beringer units, with endurance-style magnets in the pistons, which are an optional titanium alloy. This keeps the pads split during wheel changes. We used 1200R7 pads, which perform incredibly well. Thus far, this is the best caliper system we have tried.

It's been a while since we've been back to update this post for you guys, but we've had some big changes! We finally took receipt our our top-secret, Westby spec new Superbike power plant! With some tuning and good fuel, this motor made more than any other machine ever run on our dyno, producing a full 6 horsepower more than the factory BSB!

We also moved over to E/T's rake-adjust triple clamp set to achieve a perfect geometry setting for our needs.

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

-scaled-300x300.jpg)